Right-to-Left vs. Bottom-Up: Rethinking How We Plan Hardware Projects

I have a statistic that might make you spill your coffee. According to Professor Bent Flyvbjerg's massive study of over 16,000 projects, a mind-boggling 91.5% exceed budget or schedule. Only 0.5% actually hit all their targets. That's not a typo—half of one percent. If engineering projects were baseball players, they'd be batting .005.

The Planning Trap We All Fall Into

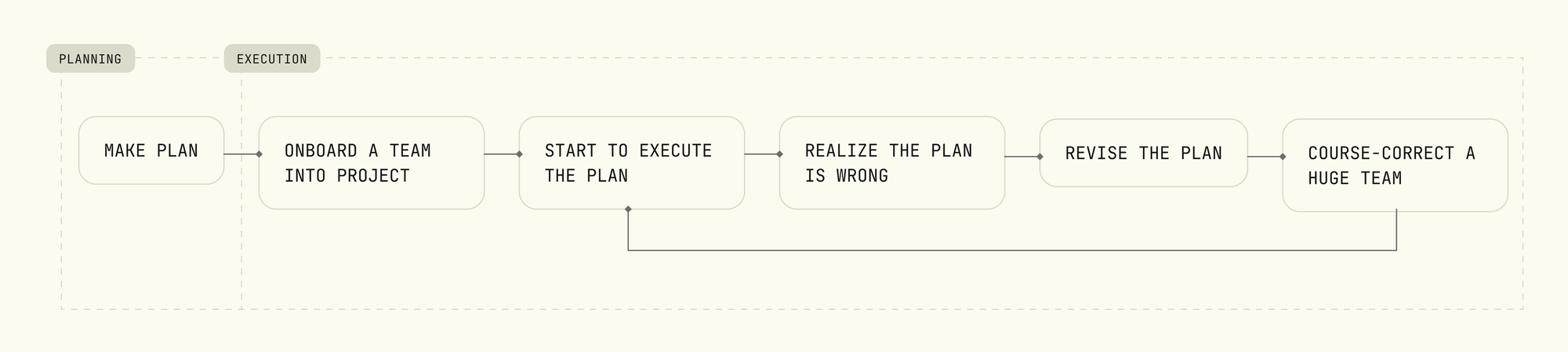

You know the drill. An engineering project leader gets excited about a brilliant new hardware concept. They immediately hire a bunch of engineers, create detailed specs, and start building. Six months later, they realize their approach is fundamentally flawed. Cue the emergency meetings, the revised timelines, and that awkward conversation with stakeholders about why everything is taking twice as long as expected.

This happens because of what Oxford professor Bent Flyvbjerg calls the "planning fallacy." As Flyvbjerg explains it, we need to start "thinking right to left" — visualizing the end result first, then figuring out what needs to happen to get there. It's surprisingly counterintuitive for most engineers.

Bottom-Up Planning: The Engineer's Comfort Zone

Let's be honest—most hardware teams default to bottom-up planning because it feels like home. It's the equivalent of organizing your sock drawer before tackling your life goals. The process typically goes something like this:

- "Let's list all the components we'll need!"

- "Now let's estimate how long each piece will take."

- "Great, now let's bundle these into larger tasks."

- "Let's create a timeline based on all these estimates."

- "And... somehow... this will all add up to our product? Right?"

This approach leverages everyone's technical expertise, and it works particularly well when facing unfamiliar challenges because it taps into the team's collective brain power.

The problem? You're so busy examining individual trees that you forget you're supposed to be building a specific forest. Teams get lost in technical details, scope creeps outward like spilled coffee, and you end up with impressive individual components that fit together about as well as mismatched LEGO sets.

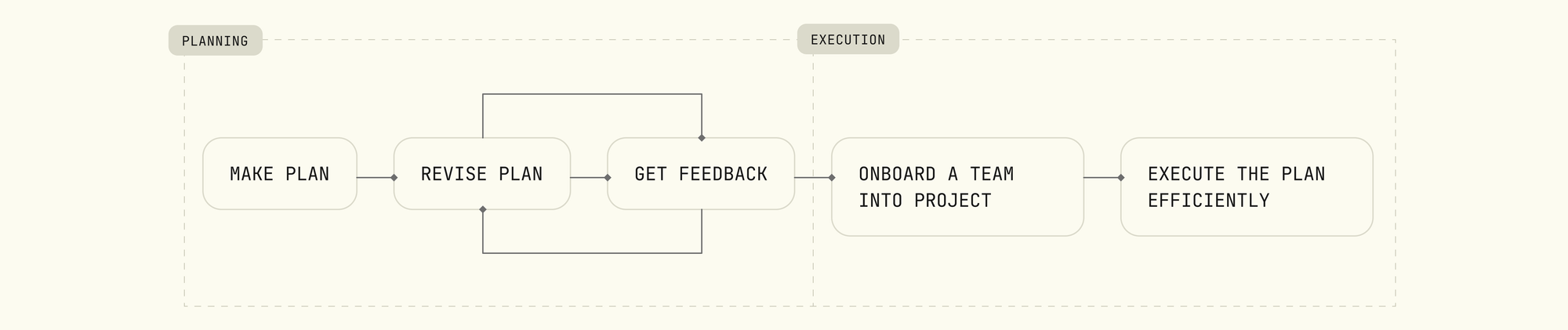

Right-to-Left Planning: Starting With the Destination

Right-to-left planning flips this on its head. Instead of starting with tasks, you begin with your destination and work backward, creating a roadmap that actually leads somewhere useful.

It works like this:

- Define exactly what success looks like (and I mean exactly)

- Identify the major milestones you'll need to hit

- Map out how these milestones depend on each other

- Break down each milestone into specific tasks

- Figure out your critical path and allocate resources accordingly

Sounds simple when we put it that way, doesn't it? But this approach has powered some of humanity's most ambitious engineering feats.

Learning from NASA's Moon Shot

When President Kennedy declared in 1961 that America would put a man on the moon within the decade, NASA had completed exactly "one 15-minute suborbital flight," as Dr. John Logsdon put it. Talk about starting from scratch. Most of us panic when asked to build something we've never built before. NASA was being asked to do something no human had ever done.

Faced with this monumental challenge, NASA didn't begin by cataloging every technical component they'd need. Instead, they started with the end goal (landing on the moon and returning safely) and broke it into distinct phases: first flying to the moon, then orbiting it, then landing an unmanned craft, and so on. Each phase became a milestone with clear success criteria.

By 1965, NASA formalized this as "Phased Project Planning" (PPP). According to NASA records, this policy came about as a response to significant problems they faced in 1964, including major delays and repeated failures in key programs.

The result? Despite setbacks (including the tragic Apollo 1 fire), they achieved Kennedy's "impossible" goal when Neil Armstrong took that famous small step on July 20, 1969.

Why We Resist Right-to-Left Planning

If right-to-left planning works so well, why don't more hardware teams use it? Here are a few patterns seen in engineering teams:

- The Technical Comfort Zone: Engineers naturally gravitate toward technical details rather than big-picture thinking.

- Traditional Training: Part of this is because most engineering education emphasizes component-level problem-solving.

- The Illusion of Control: Bottom-up planning creates a false sense of precision with all those detailed task estimates.

- The Fast-Thinking Trap: As Flyvbjerg notes, "As humans, we have a tendency to think fast – we really like to take our first thought and run with it. This causes us to act very spontaneously." Slow thinking is harder but better.

- The Execution Addiction: Engineers want to build stuff! Planning feels like a delay, even when it actually accelerates the overall project.

But here's the thing: these barriers aren't insurmountable. They just require a conscious shift in how we approach planning.

How to Start Planning Right-to-Left

Want to give right-to-left planning a shot with your hardware team? Here are five practical steps:

- Get Ridiculously Specific About Success: What will your product actually do when completed? How will you know when you're done? What metrics matter?

- Create Clear Milestones: Break the journey into 5-7 major milestones that represent significant progress. If you can't describe a milestone in a single sentence, it's not clear enough.

- Map Your Critical Path: Identify the sequence of activities that determines your minimum project timeline. This is where you should focus your best resources.

- Build in Quality Assurance: For NASA's Apollo missions, automated validation systems ensured complete dependency connections with no planning gaps. Build similar checks into your planning process.

- Simplify Your Communication: Transform your complex project plan into simple visualizations that anyone can understand. If your CEO or grandmother can't grasp your plan in five minutes, it's too complicated.

Finding the Sweet Spot: The Hybrid Approach

Now, I'm not suggesting we throw out bottom-up expertise entirely. The most effective hardware teams find a balance between the two approaches. Think of it like a construction company that starts with a top-down vision but gathers practical insights from on-site engineers who intimately understand the day-to-day challenges.

Start with right-to-left planning to establish your framework, then incorporate bottom-up input to refine and improve the plan. It's like planning a road trip by first deciding on your destination (Paris), then mapping the major waypoints (London, Channel crossing, northern France), and finally asking locals for the best specific routes between those points.

The key is maintaining the primacy of the end goal while leveraging the detailed knowledge of your technical teams. Start with right-to-left planning to establish the framework, then incorporate bottom-up input to refine and improve the plan.

The Payoff: Why It's Worth the Mental Shift

Teams that successfully implement right-to-left planning see remarkable results:

- Clearer Communication: Everyone from executives to engineers shares a common understanding of the project's purpose and progress

- More Accurate Timelines: When early delays are treated as critical issues rather than minor setbacks, problems are addressed before they cascade through the entire project.

- Better Build vs. Buy Decisions: With a clear view of the end goal, it's easier to decide what's worth developing in-house versus purchasing.

- Greater Stakeholder Alignment: From investors to team members, everyone understands what success looks like and their role in achieving it.

Think Slow, Move Fast

The next time you kick off a hardware project, resist the urge to immediately dive into component specs and task lists. Start with your destination and work backward. As counterintuitive as it seems for engineers, this approach has powered everything from moon landings to revolutionary products.

As Bent Flyvbjerg wisely advises, "You need to slow down first and think about what it is you're doing. […] And then you can move fast."

In an industry where 99.5% of projects miss their marks, right-to-left planning isn't just a better approach—it might be your only shot at joining that elusive 0.5% that succeeds on all fronts.

Ready to transform your planning process?

Check out Souffle, our specialized tool designed specifically for hardware teams implementing right-to-left planning methodology. Souffle helps you visualize goals, map dependencies, and create clear project roadmaps that keep everyone aligned.

What planning methodology does your hardware team use? Have you tried right-to-left planning? Share your experiences in the comments!

Member discussion