The 3 Questions Every Hardware Team Needs to Answer Each Morning

I've always been fascinated by the morning routines of hardware teams. Not the personal rituals of engineers—though I imagine there's a doctoral thesis waiting to be written about the correlation between caffeine consumption and debugging efficiency—but rather how these brilliant groups decide what to actually build each day.

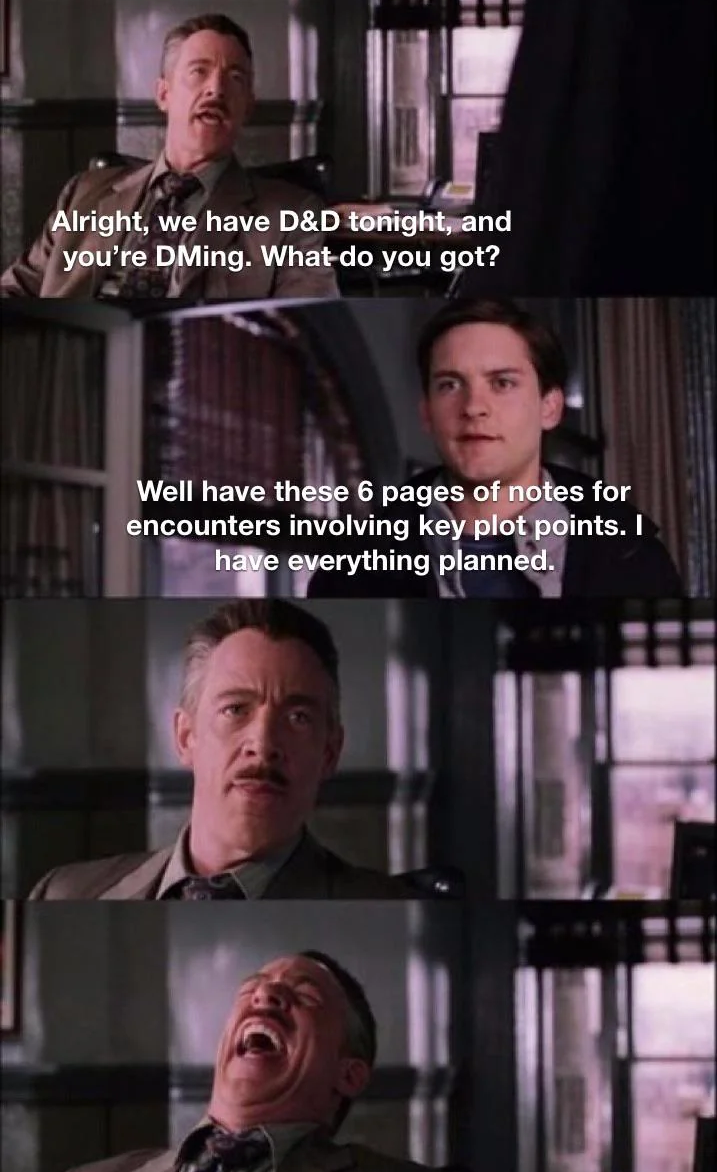

It's a bit like watching an improv. The stage is set with whiteboards covered in timelines and priorities. The players arrive clutching coffee and component reports. And then the daily performance begins: a dance of competing priorities, unexpected shortages, and the universal human tendency to focus on what's possible rather than what's important.

This scene plays out in countless hardware companies every morning. Despite meticulous engineering and careful planning, the daily decision about what specifically to build often comes down to a simple question: what parts do we actually have on hand?

If this sounds familiar, you're not alone. And more importantly, there's a better way.

When Plans Meet Reality

The problem isn't a lack of planning. Hardware teams plan extensively—sometimes exhaustively. They create detailed Gantt charts, component schedules, and assembly sequences. But as the military strategist Helmuth von Moltke the Elder famously observed, "No plan survives contact with the enemy."

In manufacturing, the enemy is reality: late shipments, quality issues, and the thousand natural shocks that hardware is heir to.

When plans collide with reality, teams typically default to what psychologist Daniel Kahneman calls the "availability heuristic." They focus on what's visible and accessible—building whatever is possible with the components at hand, regardless of strategic importance.

The consequences ripple throughout the organization:

- Customer deliveries get pushed back repeatedly as critical assemblies remain perpetually "almost done"

- Engineering changes pile up as teams struggle to incorporate updates into already-in-progress builds

- Supply chain specialists lose credibility as their carefully calculated ordering schedules bear little resemblance to actual production needs

A Morning Ritual That Actually Works

From what we've learned through conversations with numerous hardware teams, the groups that consistently hit delivery targets don't have bigger budgets or better supply chains. They just ask better questions each morning.

These successful teams structure their morning ritual around three specific questions that transform reactive building into strategic execution.

What makes these questions so powerful isn't their complexity but their simplicity. They create a natural mapping between daily decisions and customer outcomes, making it obvious what matters most.

Question 1:

Which customer orders are most at risk today?

This question immediately shifts the conversation from internal concerns to customer impact. Suddenly, the day's priorities aren't about arbitrary efficiency metrics or utilizing available inventory—they're about keeping promises to real customers.

Instead of starting with "What can we build today?" (a question that focuses on constraints), teams start with "What must we build today?" (a question that focuses on outcomes). This simple reframing completely changes how priorities are established.

The magic happens when everyone in the room—from engineering to manufacturing to supply chain—shares a clear understanding of which customer orders are approaching deadlines or facing delays. With this shared understanding, teams naturally align around common priorities without lengthy debates.

Question 2:

Which specific assemblies are blocking these at-risk orders?

With priority orders identified, the second question focuses attention on the critical bottlenecks—the specific subassemblies or components that are preventing order completion.

Instead of trying to advance all assemblies equally, teams identify the vital few that are actually on the critical path for priority orders. This prevents the common scenario where teams make progress on dozens of non-critical assemblies while the true bottlenecks remain unaddressed.

The power of this question is its specificity. Rather than generally advancing everything in production, teams can direct their limited resources precisely where they'll have the greatest impact on customer deliveries.

Picture a team that's building a complex robotics product with hundreds of components. Instead of spreading attention across all subsystems, they identify that three specific assemblies—the motor controller, the main sensor array, and the power management system—are blocking their highest priority orders. With this clarity, they can focus the day's efforts exactly where they'll matter most.

Question 3:

What specific actions will unblock these assemblies today?

The final question transforms insight into action by requiring concrete commitments. It's not enough to identify blockers—teams need clear plans to address them.

The specificity of these commitments is crucial. Vague intentions like "I'll check on that order" get replaced with concrete actions: "I'll call our supplier by 10 AM to expedite the motor controllers and update the team by lunch." These visible commitments can be tracked and followed up on, creating accountability that vague intentions never do.

When everyone leaves the morning meeting with specific actions tied to specific blockers, the entire team gains confidence that critical issues are being addressed, not just acknowledged.

In practice, this means the supply chain specialist commits to expediting particular components, the engineering lead promises to verify specifications for a troublesome assembly, and the manufacturing manager allocates specific resources to critical testing bottlenecks—all before lunch.

Putting It All Together

The beauty of this three-question framework lies in its simplicity. It doesn't require expensive software or organizational restructuring—just a disciplined approach to starting each day with the right questions in the right order.

From the hardware teams that have implemented this approach, we've heard consistent feedback about the results. Within weeks, on-time delivery rates typically improve significantly. But perhaps more surprisingly, team morale often improves as well. There's something deeply satisfying about clearly identifying problems and systematically solving them, rather than constantly reacting to the latest crisis.

This psychological shift is perhaps the most valuable outcome. The constant low-grade anxiety that accompanies reactive production—the nagging feeling that you might be working on the wrong things—is replaced by clarity and confidence.

Engineers know which specifications need immediate attention. Supply chain specialists understand which components require expediting. Manufacturing leads can give their teams clear, consistent direction. Everyone shares a common understanding of what matters most and why.

Tomorrow Morning

Of course, implementing these questions effectively requires accurate, up-to-date information about customer orders, assembly status, and component availability. While some teams manage with spreadsheets and whiteboards, the most successful ones use purpose-built tools that automate data collection and visualization.

The right tools allow teams to answer these three questions in minutes rather than hours, transforming the morning production meeting from a lengthy debugging session into a focused alignment ritual.

Imagine starting tomorrow with perfect clarity about exactly what your team should build, which components you should order immediately, and which customer deadlines are at risk.

Imagine engineering, manufacturing, and supply chain operating from a single shared understanding of priorities.

Imagine replacing daily production firefighting with systematic problem-solving and consistent progress.

It all starts with three questions:

- Which customer orders are most at risk today?

- Which specific assemblies are blocking these orders?

- What specific actions will unblock these assemblies today?

The answers might surprise you—and they'll certainly change how your team builds hardware.

At Bread Board Foundry, we're building Pretzel specifically to help hardware teams answer these three critical questions every morning. Pretzel gives you the clarity of enterprise systems without the complexity, cost, or lengthy implementation.

See how we're transforming daily production decisions at pretzel.today.

Member discussion